|

|

|

|

I-4 Ultimate Needs 150 Workers Now;

1,400 More by End of 2017

|

|

As construction activity on the I-4 Ultimate project intensifies, the need for workers rises just as rapidly.

By November 1, the I-4 Ultimate team expects to hire 150 new employees. By the end of 2017, hiring managers expect to have added about 1,400 workers to the more than 600 employees currently on the job. The project is expected to peak at 2,000 jobs.

Included in those 2,000 will be skilled construction workers from crane operators, pile drivers and heavy-equipment operators to mechanics, carpenters, welders and pipe layers. The 21-mile highway reconstruction effort needs a variety of employees. For a brief description of the work and employment benefits, visit: http://i4ultimate.com/project-info/working-on-i-4/

“We pay competitive wages and have great benefits,” said Jon Walker, I-4 Ultimate Program Project Manager for SGL Constructors. “We’ll also teach you how to be part of our culture of watching out for one another.”

To kick off the new hiring effort, SGL Constructors – the design-build joint venture for I-4 Ultimate – hosted a media event at its Recruitment and Training center in downtown Orlando. Those interested should apply at the office at 409 W. Robinson St. on Tuesdays, Thursdays and Fridays. For more information about the recruitment center, visit i4ultimate.com/jobs.

Hiring managers will consider beginners who are willing to work hard, be responsible and follow safety procedures. The team has committed to providing on-the-job training to 250 people. So far, 70 have been accepted in the training program, which offers wages and full benefits to trainees while they learn.

The employment and training center includes several heavy-equipment simulators, which allow managers and trainers to assess current abilities and teach new skills.

“You don’t need 20 years of experience to work here,” said Loreen Bobo, I-4 Ultimate Construction Program Manager for the Florida Department of Transportation. “If you’re willing to work hard and show up, you don’t have to walk in the door with a set of construction skills. We will teach you and pay you while you learn.”

|

|

|

Maitland Pedestrian Bridge Design Nearing Completion

|

|

The design of the Maitland pedestrian bridge is advancing at a healthy pace.

The 600-ft long bridge, which will cross Interstate 4 (I-4) and connect the sidewalks at Lake Destiny Road and Wymore Road, is being built in conjunction with the Maitland Boulevard interchange.

The curved bridge will be suspended over I-4 by 20 pairs of thick steel cables attached to a 142-ft high arch.

Refining the bridge’s design required research and hard work, but it’s at 90 percent completion, said Bjarne Gudmundsen, structure design build manager with SGL Constructors, the design-build joint venture of Skanska, Granite and Lane for the I-4 Ultimate Project.

“There will be a final review, and (The Florida Department of Transportation) will review it as well,” he explained. “The time in which the design advances from 90 percent to 100 percent could take up to two months, including the Release for Construction Process by FDOT. The entire design process for this bridge will total nearly a year.”

Some additions include a realignment of the pathways leading up to the bridge to allow for more visually appealing landscaping.

Beyond aesthetics, resilience against high wind speeds and other adverse weather conditions is absolutely crucial, Gudmundsen said.

A scaled model of the bridge recently underwent rigorous wind tunnel testing to study its stability.

“Even if we never have a hurricane, we need to prepare for one,” he cautioned. “Any bridge that is supported by cables, like this one, will need some kind of wind testing. The tests went well, and they confirmed our design.”

The bridge is unique, and Gudmundsen is excited to see it come to life.

“It will be a challenge to build, but it will be so rewarding once it has been completed,” he said. “We have not found a structure just like this elsewhere. When it’s done, I will be proud to walk on it.”

|

|

|

I-4 Ultimate workers beating the heat

|

|

Water bottles and shade are just as important as any tool for workers along the I-4 Ultimate project limits.

Construction activity and hot temperatures are increasing this summer, so everyone working in the field are strongly encouraged and trained in proper safety protocols.

The I-4 Ultimate project has a diverse workforce, drawing from all over the United States. Many new Florida transplants may underestimate the heat.

“We hire a lot of people from all walks of life and all different parts of the country,” said Mike Pickeral, project environmental health and safety director with SGL Constructors, the design-build joint venture for the I-4 Ultimate project. “One of the first things we do is educate and train them on proper hydration and lifestyle choices. We put a huge emphasis on hydration, due to central Florida’s significant heat index throughout the majority of the year.”

Drinking energy drinks or caffeinated drinks are discouraged, as they may reduce hydration. Frequent pauses to hydrate are highly encouraged.

“If you’re doing a light strenuous activity, like bolting something together, you want eight to 12 ounces of water every 30 to 45 minutes,” Pickeral explained. “If it’s hotter or if you’re taking on a heavier workload, you’ll increase how much you drink.”

Each SGL employee is issued a two-gallon water cooler, at their new hire orientation, which they are required to have with them at all times on the job. The foremen are also encouraged to have a five-gallon cooler to supplement any additional needs for their crew. Employees have access to the extra cooler, or are given an opportunity to refill their 2 gallon cooler if required.

Hydration is key, but there are other adjustments and strategies workers bear in mind to keep the Florida heat at bay.

“You don’t want to wear dark colored clothing, and ideally, you’ll wear clothes that can wick away the heat,” Pickeral said. “We recommend our workers wear sunscreen if they have exposed skin, but it’s common for most workers to wear long sleeves.”

Although heat management and hydration training is heavily emphasized beginning in May, workers are reminded year-round – even in winter.

“Where I’m from, in the colder climates, you can actually get dehydrated quicker,” Pickeral said. “You don’t realize how thirsty you are because you’re cooler, and your sweat is absorbed by your thick clothes. Here in Florida, we focus on hydration all year.”

|

|

|

Vacuum technology makes for safer and more efficient excavation

|

|

| |

It’s not uncommon to spot a construction worker using a shovel or operating heavy machinery to dig.

But have you ever seen someone use a vacuum?

Travel within the 21-mile limits of the I-4 Ultimate project and you might spot one of three unique vacuum excavation teams.

Large trucks equipped with a powerful vacuum and 3,000 gallons of water to soften dirt and excavate areas where shovels and heavy machinery dare not, said Larry Hill, telecoms utility engineer with SGL Constructors, the design-build joint venture for the I-4 Ultimate Project.

The dirt is stored in the truck, and later released.

The innovative method saves time guessing where utilities are and mitigates the risk of cutting into a company’s wiring and disrupting operations. Ultimately, the process is much more efficient and it saves money, said Hill, who previously worked for utility companies like AT&T.

Generally, vacuum excavation is used for smaller areas to avoid damaging utility conduits. Hill had the idea to use them for much larger areas — like a 150 ft. long hole that housed a handful of utility hubs near Maitland.

“I looked at this and knew it could have cost us a lot, and may have taken a ton of time,” Hill said. “You have to be creative, and think outside of the box. I looked at it and suggested vacuuming it out, and management went for it.”

Hill’s decision was taken into consideration, and teams eventually were dispatched to uncover utilities.

“The vacuum excavation is not abrasive, it’s quicker and you can’t really damage anything,” he said. “There’s no splicing, and there’s no service outages.”

To date, teams have used the vacuum method on two other locations, and there are applications beyond just utility work.

“It’s been used mostly for utilities, but we also use it to clean out drainage,” Hill said. “If we have some drainage and it’s filled with debris or dirt, we can just suck it all out.”

It’s also been used to clean out drainage, clear the area around large tree roots for better access, create trenches and place power poles. The suction is so powerful that it even lifted a stuck manhole cover.

“Oh, we moved it alright,” Hill said. “Think of it as a Shop-Vac on steroids.”

|

|

|

Eastbound I-4 in downtown Orlando closing nightly Aug. 12–15

|

|

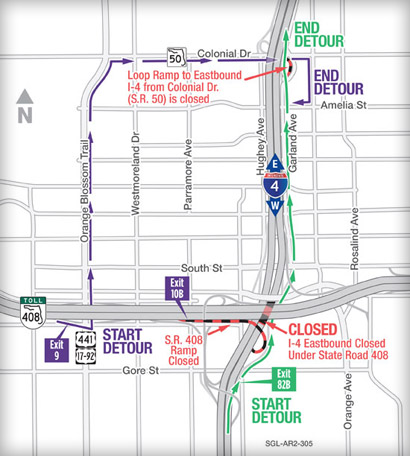

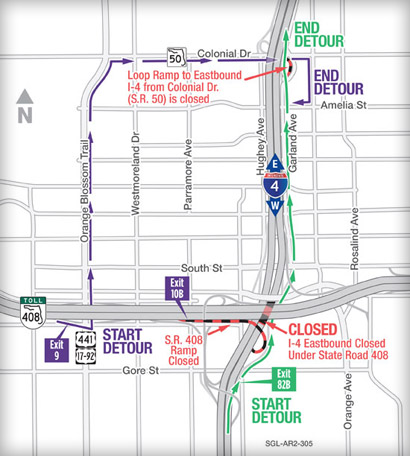

Eastbound Interstate 4 (I-4) under State Road (S.R.) 408 is closing nightly from 10 p.m. to 5 a.m. starting on Friday, August 12, through Monday, August 15, for bridge work.

The eastbound S.R. 408 exit ramp (Exit 10B) to eastbound I-4 is also closing from 10 p.m. to 5 a.m. on August 12 through August 15.

The recommended detour around this eastbound I-4 closure is to exit at South Street (Exit 82B), travel north on Garland Avenue and reenter eastbound I-4 at the ramp located after the Amelia Street intersection.

Travelers should note the S.R. 50 eastbound on ramp to I-4 is also closed and is not a recommended alternative. Motorists looking to enter eastbound I-4 from Colonial Drive are advised to enter at the ramp from Garland Avenue.

Modifications or extensions to these schedule may become necessary due to weather delays or other unforeseen conditions. Motorists are advised to maintain a safe speed when driving through the work zone.

In addition to detour signs and variable message boards in the areas of these new traffic patterns, information on closures and traffic shifts are included in I-4 Ultimate’s Advanced Construction Alert System. Sign up to receive construction alerts by text or email at i4ultimate.com.

The I-4 Ultimate project is rebuilding 21 miles of Interstate 4 (I-4) from west of Kirkman Road in Orange County to east of State Road 434 in Seminole County, adding two new dynamic tolled Express Lanes in each direction, replacing more than 140 bridges, reconfiguring 15 major interchanges and reconstructing the entire roadway.

|

|

|

Employee Spotlight: Abby Strouse

ABBY STROUSE

Environmental, Health, & Safety Intern

Summer resident of Apopka

Hometown: Clearfield, PA

Safety is more than just a field of study or set of impersonal rules for college intern Abby Strouse. Safety can save lives. Strouse knows that all too well.

Not long ago, she lost a high school classmate – a lifelong friend in Pennsylvania – to a work accident (unrelated to any I-4 Ultimate projects). “I had a friend who passed away in a trench collapse back home,” said Strouse who will be a senior at the Indiana University of Pennsylvania, where she studies Safety, Health, and Environmental Applied Sciences.

While Strouse spends the summer interning with SGL Constructors – the design-build joint venture of Skanska Granite and Lane for the I-4 Ultimate Project – she is proud to be part of a team that emphasizes safety everywhere. Even workers with desk jobs take part in the daily group exercise called Stretch and Flex, where the goal is to loosen the joints, focus the mind and remind each other to stay safe.

“I love when I come into the office for stretch and flex, and everyone is greeting each other with good mornings and hellos. It’s a great atmosphere to work in,” Strouse said.

She has witnessed that same caring approach on the construction sites, too. “I love spending time out in the field, talking to crews and getting to know who they are, what they are doing, and learning the operations they are completing. What I like the most is feeling like I belong, keeping people safe by being able to recognize potential hazards and, most importantly, sending them home to their families injury free.”

She also has been impressed that anyone on the I-4 Ultimate team can halt the work if a safety concern arises. “Everybody on the project has ‘stop-work’ authority,” she explained.

Her SGL mentor, Samantha Perry, who is Environmental, Health, and Safety Manager for Area 5, often quizzes her about their site visits and encourages her to talk with equipment operators to understand their jobs better. Instead of being a stranger, Strouse becomes a friendly listener – one willing to hear concerns.

That’s one of the unforgettable lessons of the summer: Take a personal interest in the people you want to keep safe. “If they know you, they feel more inclined to talk to you.”

|

|

|

|

|

|